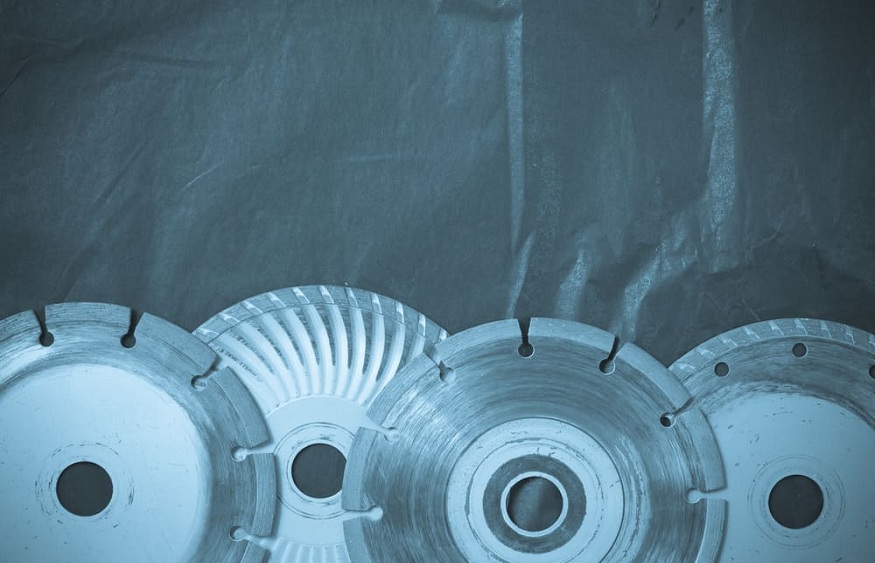

How to Make Your Diamond Saw Blades Last Longer

3 min read

If you are using diamond saw blades, you will probably be keen to get the most from them, particularly as these can be quite expensive. The experts at Devour Tools (visit website here) have a few tips for extending the life of your blades. However, they say that it is important to know when a diamond blade should be replaced as well as how long they are expected to last.

How Long Should a Diamond Saw Blade Last?

Diamond saw blades are high-performing blades capable of cutting through some of the hardest materials including concrete, steel, brick, and tile. As they are cutting through such hard substances, it is easy to assume that these blades would not last very long. Nevertheless, as they have been tipped with a mix of crushed synthetic diamonds and powdered metal, these blades are extraordinarily strong and more than capable of cutting through hard materials.

A diamond blade can vary in price, with the more expensive ones typically lasting longer (although not always). You can expect each diamond blade to be capable of cutting accurately for between 12 and 120 hours, although this entirely depends on the quality of the blade and how well the blade has been maintained.

How to Know When Your Blade Needs to be Replaced

All blades, even diamond blades, have a shelf life. Knowing when your blade needs to be replaced is important as a dull blade will not cut properly. There are a few signs that indicate a blade needs to be replaced.

For example, you might notice that the blade is cutting slower than it usually does, or that it gets stuck in the material mid-way through a cut. Furthermore, the older the blade is, the less clean a cut becomes. If you notice the cut does not look as clean as it used to, it probably indicates it’s time to change the blade.

Apart from the above, a diamond blade that looks smooth should be replaced as this means the diamond bond has worn away.

How to Make Your Blades Last Longer

It is important to match the blade to the machine and the material you are cutting. For example, a higher-performance blade should not be used in a low horsepower machine (and vice versa) if you want to get the most from the blade and the tool.

If possible, use wet cutting when using diamond cutting blades. Most materials can be cut wet, apart from wood; diamond blades are not recommended for wood anyway as they tend to tear into it, producing an unclean cut.

Wet cutting reduces heat, which in turns extends the life of the blade. It will also decrease dust and cut down on debris flying around, generally creating a safer work environment.

Make sure to clean your blades after use. The best way to clean a diamond blade is to run it over a piece of concrete for about fifteen seconds to remove the grit and grime that may have become attached during use.

While it is preferable to use wet cutting, it is not always possible. If you must dry cut, make sure that the blade does not overheat. You can do this by allowing the blade to free spin in the air every so often to help cool down. Taking regular rests in between cutting will also help to this effect.

Be sure to mount your blade properly as this will prevent it from wearing down too quickly. It is always a good idea to familiarize yourself with the saw before you start to use it by reading the user manual fully.